Traditional rigid robots face significant limitations when it comes to performing certain tasks that require flexibility or human interaction. Soft-bodied robots, with their pliable structures, offer remarkable advantages in safely working alongside people and navigating confined spaces. However, a fundamental challenge has always been enabling these flexible machines to accurately track their own body parts as they deform—a complex problem given that soft robots can theoretically morph in infinite ways.

MIT researchers have pioneered an innovative AI algorithm that assists engineers in developing soft robots with enhanced environmental awareness. This deep learning soft robot design automation system determines optimal sensor placement within the robot's structure, dramatically improving its ability to interact with surroundings and execute designated functions. This breakthrough represents significant progress toward fully automated robot design. "Our system doesn't just master specific tasks—it simultaneously learns how to craft the most effective robot structure for solving those tasks," explains Alexander Amini. "Finding the right sensor locations has traditionally been an incredibly complex challenge, making this solution particularly groundbreaking."

The findings were unveiled at the IEEE International Conference on Soft Robotics in April, with a full publication in the esteemed journal IEEE Robotics and Automation Letters. Leading the research were PhD candidates Alexander Amini and Andrew Spielberg from MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL), collaborating with fellow PhD student Lillian Chin and professors Wojciech Matusik and Daniela Rus.

Developing soft robots capable of real-world applications has long represented one of robotics' most persistent challenges. Unlike their rigid counterparts—which benefit from limited motion ranges that simplify algorithmic control—soft robots present uniquely complex computational problems. Their flexible, deformable nature makes them more akin to responsive bouncy balls than predictable bowling balls, creating significant design and control obstacles.

"The core challenge with soft robots lies in their virtually infinite dimensionality," notes Spielberg. "Any point on a soft robot can theoretically deform in countless directions." This characteristic makes mapping body positions exceptionally difficult. Previous approaches typically relied on external cameras to track the robot's configuration and relay this information to control systems. However, the MIT team sought to create fully autonomous soft robots independent of external monitoring systems.

"Practically speaking, you can't attach infinite sensors to a robot," Spielberg points out. "So the critical questions become: how many sensors are necessary, and where should they be positioned for maximum effectiveness?" The team turned to neural network sensor placement robotics to find the answer.

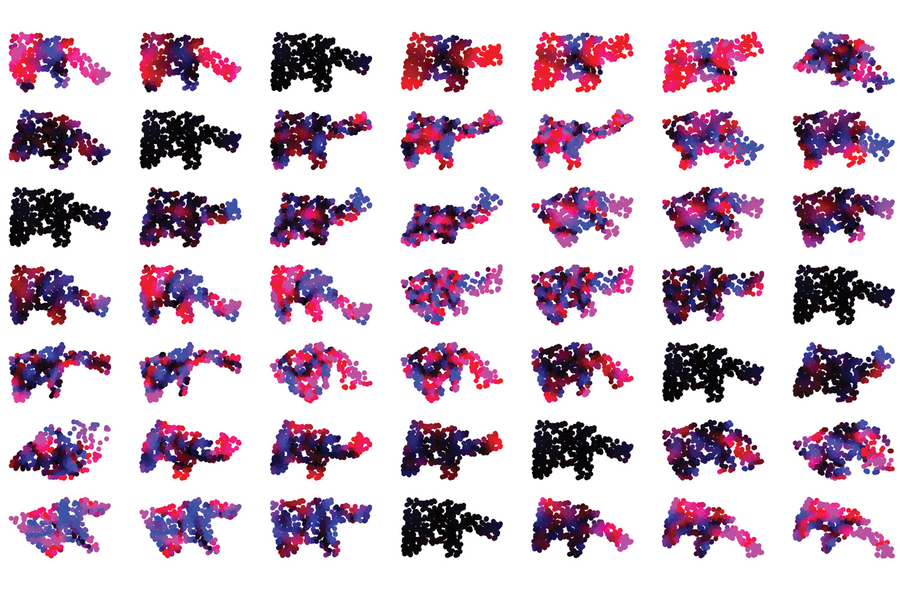

The researchers created a novel neural network architecture that simultaneously optimizes sensor positioning and learns efficient task completion strategies. Their approach involved dividing the robot's body into smaller units called "particles," with each particle's strain rate serving as input to the neural network. Through iterative learning processes, the network discovered optimal movement sequences for various tasks, such as grasping objects of different sizes. Concurrently, the system tracked which particles were most frequently utilized, gradually eliminating less critical particles from subsequent trials.

By identifying the most essential particles, the network effectively determined ideal sensor locations to ensure peak performance. For instance, with a simulated grasping hand, the AI algorithm for soft robot sensor optimization might recommend concentrating sensors in and around the fingers—where precise environmental interaction proves crucial for object manipulation. While this might seem intuitively obvious, the algorithm dramatically outperformed human intuition regarding sensor placement.

The research team tested their algorithm against expert predictions across three different soft robot configurations. They asked experienced roboticists to manually select sensor locations for efficient task completion, then compared performance between human-designed and algorithm-designed sensor layouts. The results were decisively in favor of the AI system. "Our model substantially outperformed human experts across every task," admits Amini. "Even after examining some robot designs and feeling confident about optimal sensor placement, I was surprised by how much subtlety the problem contained that we hadn't initially considered."

Spielberg believes their work could significantly advance robot design automation. Beyond developing movement control algorithms, "we must also consider how to effectively sensorize these robots and how these sensory systems interact with other components," he explains. Enhanced sensor placement could yield immediate industrial benefits, particularly for applications requiring precise manipulation. "In scenarios demanding sophisticated, optimized touch sensitivity, our technology offers potential for immediate practical implementation," Spielberg adds.

"Automating the design of sensor-equipped soft robots represents a crucial step toward rapidly creating intelligent tools that assist with physical tasks," emphasizes Rus. "Sensors enable soft robots to effectively 'see' and comprehend their environment and their relationship with it—a fundamental capability for autonomous operation."

This research received support from the National Science Foundation and the Fannie and John Hertz Foundation.