The Boston metropolitan area has established itself as a global epicenter for pharmaceutical innovation, consistently producing groundbreaking medications that transform patient care. However, the traditional model of manufacturing these drugs for clinical trials has historically relied on complex international partnerships and fragmented supply chains. The inherent vulnerabilities of this system became strikingly evident during the unprecedented challenges of the Covid-19 pandemic.

Enter Snapdragon Chemistry, an innovative company co-founded by MIT Professor and Associate Provost Tim Jamison, which is revolutionizing how pharmaceutical companies approach drug manufacturing. By implementing AI-powered local production systems, Snapdragon is dramatically reducing the timeline for new medications to reach patients in need.

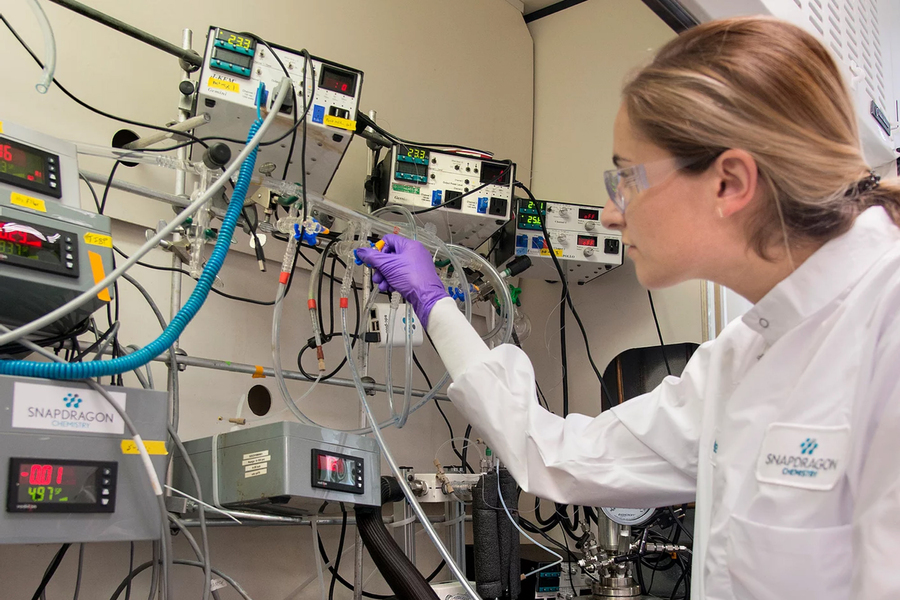

Snapdragon operates at the intersection of chemistry and cutting-edge technology, functioning as an advanced laboratory that conducts sophisticated experiments for pharmaceutical clients to create complex molecules. The company then leverages artificial intelligence and automation to streamline production processes, often significantly reducing the number of steps required to synthesize these molecules. When the optimized process requires specialized technology—such as a state-of-the-art chemical reactor—that the client lacks, Snapdragon designs and builds the equipment while providing comprehensive training on its integration into existing workflows.

While some of these innovative reactors are being utilized for commercial production of approved medications, the majority are specifically engineered to help pharmaceutical and biotechnology companies navigate the clinical trial phase with unprecedented speed and efficiency.

"At the clinical stage, the primary objective is maximum velocity to determine whether a therapeutic candidate holds genuine promise," explains Snapdragon CEO Matt Bio. "Our strategic focus remains firmly on developing and implementing technologies that deliver drugs to the clinic in record time."

With a portfolio of over 100 clients, spanning from emerging biotech startups to pharmaceutical giants like Amgen, Snapdragon has made significant contributions to drug development, including potential breakthrough cancer treatments. The company has also collaborated with prestigious research agencies to expand the boundaries of automated material production, notably partnering with the Biomedical Advanced Research and Development Authority (BARDA) to produce ribonucleotide triphosphates—essential building blocks for mRNA-based Covid-19 vaccines.

In a significant expansion move, Snapdragon announced plans in March to construct a 51,000 square foot advanced facility in Waltham, Massachusetts. This strategic investment will substantially increase the company's in-house production capabilities, eliminating yet another bottleneck in the journey of new drugs from laboratory to clinic.

"Our mission centers on providing clients with the most efficient pathway to the molecules they need for clinical testing," Bio emphasizes. "By integrating machine learning algorithms and advanced automation, we're creating unprecedented efficiencies in drug development."

Through its specialized focus on chemical synthesis processes and transformative technologies, Snapdragon believes it has the potential to revolutionize the economics of drug manufacturing at every scale—from laboratory research to commercial production.

"We can potentially manufacture medications at a fraction of current costs," Bio notes. "This opens fascinating possibilities, such as developing a tuberculosis drug for just half a cent per dose. While creating such ultra-low-cost medications presents unique challenges compared to complex drugs, it's essential for widespread distribution in regions like sub-Saharan Africa. These represent the kinds of meaningful opportunities our technology enables us to pursue."

From Concept to Reality

Jamison's entrepreneurial journey began when he recognized significant industry interest in his pioneering research on continuous flow photochemistry—a technique that utilizes light to initiate chemical reactions and offers substantial cost and scalability advantages over traditional batch processing methods.

"Historically, chemistry has been conducted in what we term batch mode since its inception," explains Jamison, who also served as a principal investigator at the Novartis-MIT Center for Continuous Manufacturing and has authored numerous publications on continuous flow chemistry processes. "It's comparable to cooking—we prepare a specific quantity, and that constitutes a batch. However, if you're operating as a food manufacturer, you'd implement continuous processes to meet throughput demands, similar to an assembly line."

In 2012, Jamison began conceptualizing a potential company with eventual co-founder Aaron Beeler, an associate professor of medicinal chemistry at Boston University. Following two years of intensive development, validation, and "pressure testing" of their business model—with guidance from industry colleagues and MIT's Venture Mentoring Service—the founders established a company focused on manufacturing specialty and fine chemicals, particularly those well-suited for continuous flow synthesis. Snapdragon officially launched in October 2014 under the name Firefly Therapeutics.

Jamison often remarks that the company pivoted on its very first day. Within a week of incorporation, the founders had secured two contracts—not to sell chemicals, but to assist pharmaceutical companies in developing continuous manufacturing processes.

Bio joined the organization in 2015, when the company—by then renamed Snapdragon—had established consulting and services contracts. Snapdragon's client base was expanding so rapidly that the company relocated four times during its initial four years, evolving from requiring a single laboratory bench to needing dozens of workstations.

While Snapdragon's core service remains helping companies optimize chemistry processes, the approach has evolved significantly. Most improvements now stem from a sophisticated understanding of how cutting-edge reactor technology and advanced automation systems can transform traditional workflows.

"If you toured our laboratories today, you'd observe extensive automation and robotics performing tasks that scientists previously handled with lower efficiency," Bio explains. "Rather than spending time manually setting up and dismantling reactions, our scientists can focus entirely on the chemistry itself, leveraging robotic tools to obtain answers more rapidly and accurately."

"One area where Snapdragon is truly pioneering innovation is in laboratory operating systems—sophisticated platforms that network every instrument throughout the company and collect real-time process data," Jamison adds. "This integrated approach to data collection and analysis represents a fundamental shift in how pharmaceutical research is conducted."

Realizing Industry Transformation

The planned expansion of Snapdragon's Waltham facility brings the company full circle, returning to the co-founders' original vision of in-house specialty chemical production.

Bio notes that this expansion will particularly benefit development of treatments for diseases affecting smaller patient populations and requiring less material. He points out that in certain mRNA-based therapies, for instance, a single kilogram of material can potentially treat millions of patients—a remarkable efficiency that transforms the economics of drug development.

The company has also recently secured a grant from DARPA to explore converting abundant domestic commodities, such as natural gas and agricultural waste, into starting materials for high-value pharmaceuticals. This initiative could significantly reduce reliance on international supply chains while creating new economic opportunities.

Looking ahead, Jamison believes Snapdragon's technology-driven production processes will increasingly accelerate the company's capacity for innovation.

"The chemistry of tomorrow may look radically different from current practices, but we lack sufficient data to fully envision these changes yet," Jamison reflects. "One of Snapdragon's long-term visions involves creating automated systems capable of generating vast datasets, which can then serve as training material for machine learning algorithms across numerous applications—from optimizing synthesis pathways to predicting material properties. This approach unlocks extraordinary possibilities for pharmaceutical innovation and beyond."