MIT researchers have developed an groundbreaking artificial intelligence system that autonomously designs and fabricates sophisticated robotic components known as actuators. This innovative technology optimizes these complex parts according to countless specifications, accomplishing what would be virtually impossible for human engineers to achieve manually.

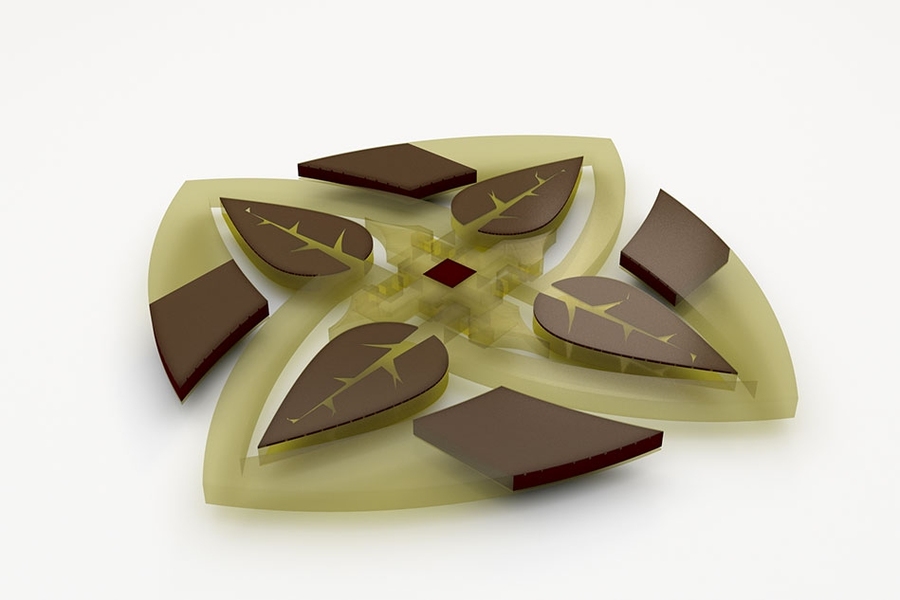

In a groundbreaking study published in Science Advances, the research team showcases their system by creating actuators—mechanical devices that control robotic systems through electrical signals—that display distinct black-and-white images when viewed from different angles. One remarkable example shows a Vincent van Gogh portrait when positioned flat, yet reveals the famous Edvard Munch masterpiece "The Scream" when tilted at a specific angle upon activation. The team also successfully 3D printed aquatic water lilies featuring petals embedded with actuator arrays and hinges that respond to magnetic fields by folding elegantly.

These revolutionary actuators are constructed from a combination of three specialized materials, each possessing unique properties such as specific light or dark coloring, flexibility, and magnetization characteristics that dictate the actuator's response to control signals. The sophisticated software first deconstructs the actuator design into millions of three-dimensional pixels, or "voxels," with each voxel capable of containing any of the three materials. The system then executes millions of simulations, testing different material combinations within each voxel until discovering the optimal configuration to produce two distinct images at different angles. A specialized 3D printer subsequently fabricates the actuator by precisely depositing the appropriate material into each designated voxel, building the object layer by layer.

"Our ultimate goal is to automatically discover an optimal design for any given challenge, then utilize our optimized design output to manufacture it," explains lead author Subramanian Sundaram PhD '18, a former graduate student in MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL). "We've created a nearly fully automated process that encompasses everything from material selection to design optimization to final product fabrication."

The transformative image-displaying capability demonstrates just one aspect of the system's potential. Actuators optimized for both appearance and functionality could significantly advance biomimetic robotics. For instance, researchers are developing underwater robotic skins featuring actuator arrays designed to imitate the denticles found on shark skin. These denticles work collectively to reduce drag, enabling faster, quieter swimming. "One can envision underwater robots covered entirely with actuator arrays on their surface, optimized for efficient drag reduction and maneuverability," Sundaram notes.

Contributing authors alongside Sundaram include: Melina Skouras, a former MIT postdoc; David S. Kim, a former researcher in the Computational Fabrication Group; Louise van den Heuvel '14, SM '16; and Wojciech Matusik, an MIT associate professor in electrical engineering and computer science and head of the Computational Fabrication Group.

Mastering the Combinatorial Complexity

Modern robotic actuators are growing increasingly sophisticated. Depending on their application, they must be optimized for numerous parameters including weight, efficiency, appearance, flexibility, power consumption, and various other performance metrics. Traditionally, experts have manually calculated all these parameters to identify optimal designs.

This complexity is further compounded by advanced 3D-printing techniques that can now utilize multiple materials within a single product, dramatically increasing the design's dimensionality. "What results is what we call a 'combinatorial explosion,' where the number of possible material and property combinations becomes so vast that evaluating each possibility to create an optimal structure becomes practically impossible," Sundaram explains.

For their research, the team first customized three polymer materials with specific properties required for their actuators: color, magnetization, and rigidity. They ultimately created a nearly transparent rigid material, an opaque flexible material serving as hinges, and a brown nanoparticle material responsive to magnetic signals. They incorporated all this characterization data into a comprehensive property library.

The system accepts grayscale image examples as input—such as the flat actuator displaying the Van Gogh portrait that tilts at a precise angle to reveal "The Scream." It essentially executes a sophisticated trial-and-error process comparable to solving a Rubik's Cube, but with approximately 5.5 million voxels being iteratively reconfigured to match target images while achieving specific angular measurements.

Initially, the system draws from the property library to randomly assign different materials to various voxels. It then runs simulations to determine if that arrangement successfully displays both target images when viewed straight on and at an angle. If not, it receives an error signal identifying which voxels are correctly positioned and which require modification. For instance, adding, removing, or repositioning brown magnetic voxels will alter the actuator's angle when exposed to a magnetic field. However, the system must simultaneously consider how aligning these brown voxels will impact the resulting image.

Precision at the Voxel Level

To calculate the actuator's appearance at each iteration, the researchers employed a computer graphics technique called "ray-tracing," which simulates how light interacts with objects. Simulated light beams pass through each column of voxels within the actuator. These actuators can be fabricated with more than 100 voxel layers, with columns potentially containing over 100 voxels with different material sequences that produce varying shades of gray when flat or angled.

When the actuator lies flat, for example, a light beam might illuminate a column containing numerous brown voxels, creating a dark tone. However, when the actuator tilts, the beam will interact with misaligned voxels. Brown voxels may shift away from the beam's path while clearer voxels move into it, producing a lighter tone. The system utilizes this technique to position dark and light voxel columns precisely where needed for both the flat and angled images. After 100 million or more iterations—taking anywhere from a few hours to several days—the system identifies an arrangement that accurately reproduces the target images.

"We're comparing what each voxel column looks like when flat versus when tilted to match our target images," Sundaram explains. "If they don't match, we might swap a clear voxel with a brown one. If that improves the result, we keep this new configuration and continue making other changes repeatedly until achieving the desired outcome."

To fabricate these actuators, the researchers constructed a custom 3D printer employing a "drop-on-demand" technique. Containers holding the three materials connect to print heads featuring hundreds of individually controlled nozzles. The printer precisely releases 30-micron-sized droplets of the designated material into each corresponding voxel location. Upon landing on the substrate, each droplet solidifies, allowing the printer to construct the object layer by layer with remarkable precision.

This research could serve as a foundation for designing larger structures, such as airplane wings, Sundaram suggests. Researchers have begun exploring similar approaches, breaking down airplane wings into smaller voxel-like blocks to optimize designs for metrics including weight and lift. "While we're not yet capable of printing wings or structures of that scale or with those specific materials, I believe this represents a significant first step toward that ambitious goal," Sundaram concludes.