Engineers tasked with creating innovative materials and protective coatings face an overwhelming challenge: navigating through billions of potential combinations. Traditional testing methodologies, whether laboratory experiments or comprehensive computer simulations, require substantial time investments—often consuming hours, days, or even longer to analyze just a single variation. However, groundbreaking artificial intelligence technology pioneered by MIT researchers has dramatically transformed this landscape, reducing evaluation time to mere milliseconds and enabling efficient screening of extensive material candidate libraries.

This revolutionary system, documented in a publication in the prestigious journal Matter, represents a collaborative effort between MIT postdoc Chi-Hua Yu, civil and environmental engineering professor and department head Markus J. Buehler, and Yu-Chuan Hsu at the National Taiwan University. The researchers envision applications ranging from developing enhanced protective coatings to creating superior structural materials capable of safeguarding aircraft and spacecraft against impact damage.

The research concentrates on forecasting material failure patterns by examining crack propagation through molecular structures. Professor Buehler and his research team have dedicated years to meticulously studying fractures and various failure mechanisms, recognizing that understanding these processes is fundamental to engineering durable, dependable materials. "Our laboratory specializes in molecular dynamics simulations—essentially atom-by-atom computational modeling" of such phenomena, Buehler explains.

These simulations provide chemically precise representations of fracturing processes, but their computational intensity presents significant challenges. "The time required to simulate these processes is substantial," Buehler acknowledges. This limitation prompted the research team to investigate machine learning approaches to optimize the workflow.

"We're essentially taking an innovative shortcut," Buehler notes. "We questioned whether we could simply provide observations of fracturing behavior [in specific materials] and allow computers to independently learn these relationships." For artificial intelligence systems to accomplish this, they require diverse training examples to establish correlations between material characteristics and performance outcomes.

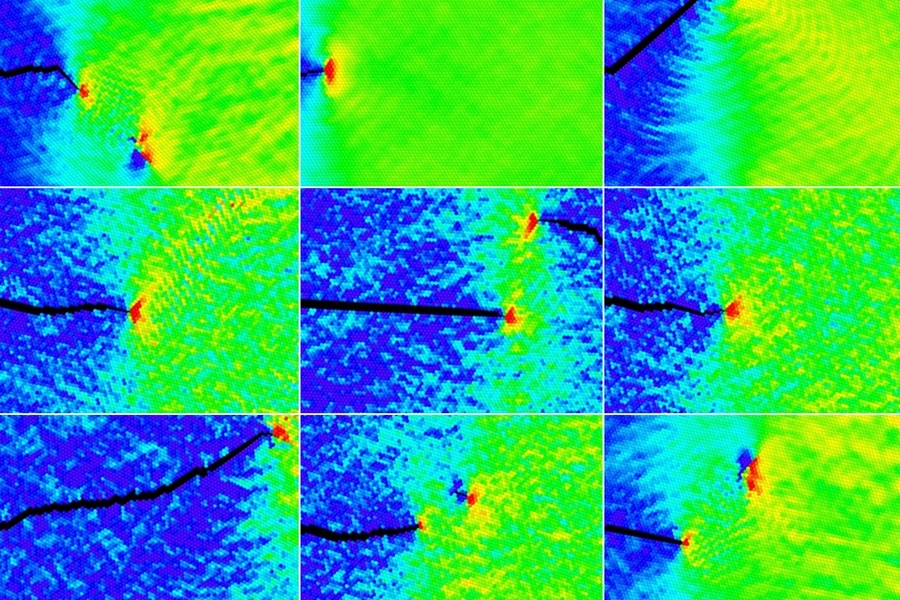

In their research, the team examined various composite, layered coatings composed of crystalline materials. Variables included layer composition, relative orientations of crystal structures, and material responses to fracturing based on molecular dynamics simulations. "We systematically simulate, atom by atom, how materials fracture, and document this comprehensive data," Buehler states.

The research team employed atom-by-atom simulations to analyze crack propagation through different materials. This animation demonstrates one such simulation, showing complete crack progression through the material structure.

The researchers meticulously generated hundreds of simulations featuring diverse structural configurations, subjecting each to numerous simulated fracture scenarios. They subsequently fed extensive datasets from these simulations into their AI system to determine whether it could identify underlying physical principles and predict performance for materials not included in the training set.

The system succeeded remarkably. "That's the truly exciting aspect," Buehler enthuses. "The AI-powered computer simulation accomplishes what traditionally requires extensive time using molecular dynamics or finite element simulations—another engineering approach that's similarly time-consuming. This represents an entirely new methodology for simulating material failure."

Understanding material failure mechanisms constitutes critical information for any engineering endeavor, Buehler emphasizes. Material failures such as fractures "rank among the primary causes of losses across all industries. For inspecting aircraft, trains, automobiles, roadways, infrastructure, concrete, steel corrosion, or even understanding bone fractures in biological tissues, the capability to simulate fracturing with artificial intelligence—rapidly and efficiently—represents a genuine game-changing advancement."

The speed enhancement achieved through this methodology is extraordinary. Hsu explains that "while single molecular dynamics simulations have required several hours to complete, our artificial intelligence predictions require merely 10 milliseconds to process all pattern-based predictions and demonstrate crack formation progression step by step."

"Over approximately the past three decades, researchers have developed multiple approaches to model crack propagation in solids, yet it remains a formidable and computationally expensive challenge," notes Pradeep Guduru, an engineering professor at Brown University who was not involved in this research. "By shifting computational demands to training a robust machine-learning algorithm, this new approach potentially yields a rapid and computationally efficient design tool—always desirable for practical applications."

The methodology demonstrates considerable versatility, according to Buehler. "Although our paper specifically applied it to one material with different crystal orientations, this approach can be extended to significantly more complex materials." Additionally, while the team utilized atomistic simulation data, the system can also make predictions based on experimental data, such as images capturing material fracturing processes.

"If we encounter a novel material we haven't previously simulated," Buehler explains, "and we possess extensive images documenting its fracturing process, we can incorporate that data into the machine-learning model as well." Regardless of input source—simulated or experimental—the AI system analyzes the evolving process frame by frame, identifying differences between consecutive images to learn underlying dynamics.

For instance, as researchers leverage new facilities at MIT.nano—the Institute's dedicated center for nanoscale material fabrication and testing—substantial quantities of data about various synthesized materials will become available.

"As we develop increasingly sophisticated high-throughput experimental techniques capable of rapidly generating numerous images automatically, these data sources can be immediately integrated into machine-learning models," Buehler predicts. "We anticipate a future with significantly enhanced integration between experimentation and simulation—far beyond what we've experienced historically."

The system could extend beyond fracturing—the focus of this initial demonstration—to numerous time-dependent processes, including material diffusion or corrosion mechanisms. "Whenever we encounter evolving physical fields and need to understand their progression as a function of microstructure," Buehler suggests, "this methodology could prove tremendously valuable."

This research received support from the U.S. Office of Naval Research and the Army Research Office.