When Peter Howard SM '84, CEO of Realtime Robotics and MIT Sloan School of Management graduate, identifies the primary challenge facing the robotics sector, he immediately points to return on investment concerns. "While robotic automation can perform nearly any task a human can, the ROI remains unattractive because of expensive deployment processes and insufficient throughput," Howard explains.

However, Realtime Robotics has engineered an innovative combination of proprietary software and hardware that slashes system deployment time by over 70%, cuts deployment costs by more than 30%, and reduces the programming requirements for building robotic systems by up to 90%. Essentially, Realtime Robotics is transforming robot adoption into a highly worthwhile investment through their AI-powered robot motion planning technology.

Human beings constantly engage in planning, whether we realize it or not. We organize our daily activities: morning meals, professional commitments, appointments, lunch breaks, errands, and so forth. On a subconscious level, even the simple journey from your workstation to the coffee maker involves countless micro-decisions that enable you to navigate from point A to point B without collisions. Remarkably, our brains continuously process decisions that help us navigate our physical surroundings until we enter sleep mode.

In robotics terminology, the computational process of optimally moving a robot from one location to another without collisions is known as motion planning. For three decades, this has represented a significant challenge for the industry, because effective motion planning essentially involves equipping robots with decision-making capabilities (intelligence) to accomplish their objectives autonomously. To be practical, this planning must occur in real-time to address variables that emerge in actual scenarios. Additionally, when robots operate alongside other robots or humans, their movements require coordination with their counterparts.

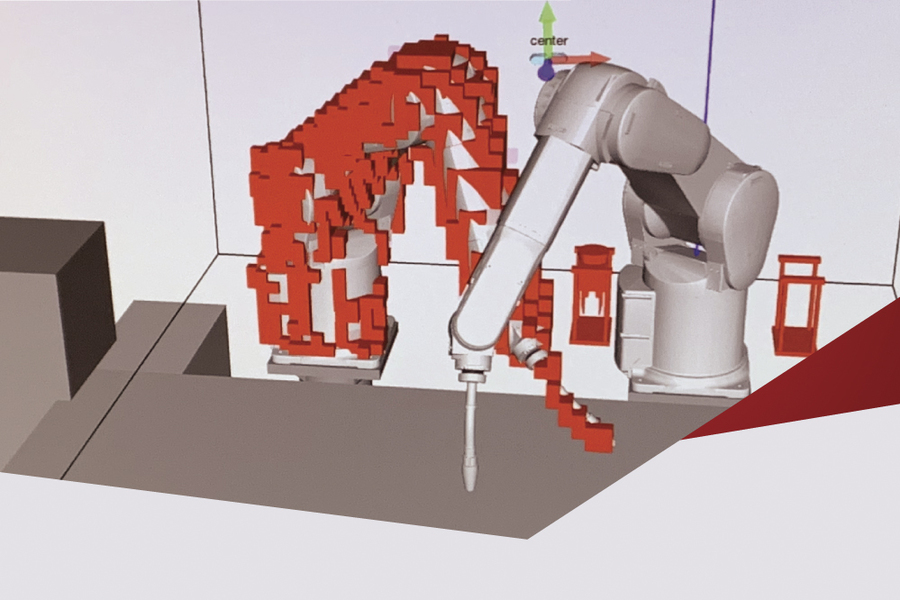

Traditional motion planning has depended on inflexible software that restricts robots to following predetermined motion paths based on rigid decision trees. This laborious process can demand days, weeks, or even months of point-by-point programming, which must account for all potential scenarios to determine the optimal, collision-free route for the robot. The reality is that this approach has consistently been too sluggish for effective implementation in robot and autonomous vehicle applications within dynamic environments like factory floors shared by both robots and humans.

This landscape changed when Realtime Robotics introduced their solution featuring autonomous robot motion planning and multi-robot deconfliction. They've developed a platform incorporating a specialized processor designed specifically to generate autonomous, collision-free motion plans for multiple robots simultaneously.

Founded on research by co-founder George Konidaris, a former MIT postdoc in the Department of Electrical Engineering and Computer Science, the core technology is implemented in an industrial PC called the Realtime Controller. This system precomputes thousands or even millions of potential motions the robot might require, then utilizes hardware acceleration to search through these motions during operation.

"Our technology evaluates all potential options, moment-to-moment and millisecond-to-millisecond, identifying which paths are available, then determining the optimal route through the workspace to accomplish the task," Howard states.

The company has integrated AI-for-multiple-robot optimization to identify the most efficient configuration for the work cell—encompassing everything from robot positioning to task sequencing and assignment. "By running this AI for merely a few hours, you can achieve throughput levels that exceed what human programmers could possibly accomplish," Howard elaborates. "Our platform enables new AI-based system developers to concentrate on their strengths, while we handle the complex challenges inherent in robotics."

The Realtime Robotics platform also incorporates sophisticated spatial and object perception systems for collision avoidance and workpiece recognition, delivering exceptional flexibility while ensuring the safety of human coworkers. "We're introducing the first system capable of close interaction with people while maintaining their safety in environments with industrial robots," Howard asserts.

In May 2017, Realtime Robotics established operations at MassRobotics, a Boston-based robotics collective. Three months later, they completed their initial seed funding round and secured their first contract with Amazon Robotics. A year after that, they demonstrated their breakthrough demonstration to an audience including two of the world's top six robot manufacturers.

Howard acknowledges that their strong MIT connections significantly contributed to gaining industry attention. "MIT ILP [Industrial Liaison Program] and the Startup Exchange maintain excellent relationships at MassRobotics and throughout Boston's robotics ecosystem—they consistently brought world leaders in the robotics industry through our facility."

Under Howard's leadership, Realtime Robotics' go-to-market strategy focuses on reaching end users through partnerships with leading industrial manufacturers as non-exclusive collaborators. Most recently, they've joined forces with Siemens Digital Industries software division to help original equipment manufacturers (OEMs) reduce deployment time and adapt to changes during simulation and on the factory floor.

Regarding practical applications, Howard highlights Realtime Robotics' recent collaboration with Toyota. After completing the initial three phases of a multi-stage project, they're now moving to implementation on the automotive manufacturer's factory floor. Currently, they're managing a multi-robot cell with four robots on the production line. However, expansion to additional applications and facilities across North America is imminent.

The impact of Realtime Robotics extends beyond factory environments. Autonomous vehicles (AVs) will benefit significantly from risk-aware motion planning. Realtime Robotics' specialized technology, known as Lightning, can process hundreds of potential forecasts per sensor cycle. This enables AV stack partners to consider numerous possibilities and their probabilities—as identified by Realtime Robotics' sensors and autonomous robot collision avoidance systems—to calculate the optimal immediate motion plan that ensures safety in anticipation of these scenarios.

Realtime Robotics currently has global automation OEM leaders promoting their products, with top 10 automakers implementing initial product rollouts while incorporating this revolutionary technology into their standard tools and workflows. "With groundbreaking new capabilities for optimization and safety being added to our platform, along with additional funding, the next six months promise to be exceptionally exciting," Howard concludes.