What separates successful companies in their implementation of artificial intelligence and data analytics for manufacturing and operations? How do industry leaders maintain their competitive edge, and what valuable insights can other businesses gain from their experiences?

The MIT Machine Intelligence for Manufacturing and Operations (MIMO) in collaboration with McKinsey and Company provides groundbreaking answers in a pioneering Harvard Business Review publication. This comprehensive analysis details how MIMO and McKinsey joined forces to conduct an extensive survey of 100 enterprises, uncovering how top-performing organizations effectively leverage machine learning technologies while identifying improvement opportunities for others.

Established by the MIT Leaders for Global Operations (LGO) program, MIMO represents an innovative research and educational initiative aimed at enhancing industrial competitiveness through accelerated deployment and understanding of machine intelligence. "Our mission is to discover the most efficient path from data collection to tangible business impact," explains Bruce Lawler SM '92, the program's managing director.

The McKinsey collaboration perfectly embodies MIMO's core objective of demystifying effective machine learning implementation. The research examined organizations across various sectors, evaluating their digital infrastructure, data analytics capabilities, and machine intelligence technology adoption. The assessment also analyzed their strategic objectives—from operational efficiency to enhanced customer experience and reduced environmental footprint—alongside their performance tracking methodologies. Survey participants were recruited from MIT and McKinsey's extensive professional networks.

"This research represents one of the most comprehensive studies in our field, encompassing 100 companies and evaluating 21 distinct performance indicators," notes Vijay D'Silva SM '92, a senior partner at McKinsey and Company who collaborated closely with MIMO on this initiative.

The findings revealed that organizations achieving the most significant benefits from digital transformation demonstrated robust governance structures, effective deployment strategies, strategic partnerships, employees with specialized machine learning training, and comprehensive data accessibility. Notably, these leading companies invested up to 60% more in machine learning technologies compared to their industry peers.

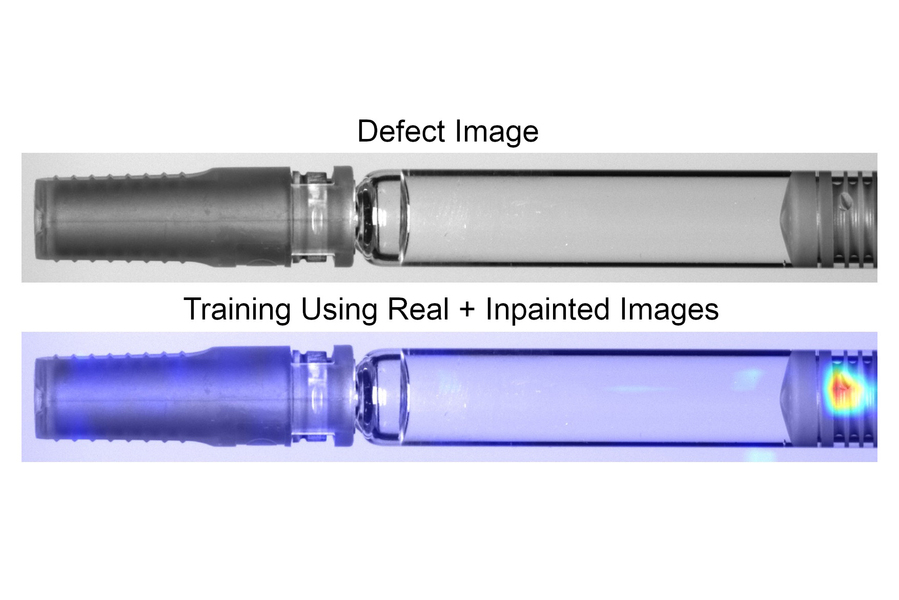

Biopharmaceutical leader Amgen exemplifies successful implementation, utilizing deep-learning image-augmentation techniques to optimize their visual inspection systems. This innovative approach has yielded remarkable results, enhancing particle detection by 70% while substantially reducing the need for manual inspections. AJ Tan PhD '19, MBA '21, SM '21 played a pivotal role in this project, documenting his findings in an LGO thesis that earned last year's Best Thesis Award during graduation ceremonies.

Lawler emphasizes that Tan's work perfectly illustrates MIMO's critical mission of bridging the gap between advanced machine learning applications and traditional manufacturing processes before industry transformations become unavoidable.

"We recognized the urgent need to integrate these powerful new technologies into manufacturing more rapidly," Lawler states. "Over the next two to three decades, our global population will increase by approximately 3 billion people, all aspiring to the quality of life we currently enjoy. These lifestyles depend on manufactured goods. The challenge becomes: how can we more effectively convert natural resources into human wellbeing? Manufacturing represents one of the primary mechanisms for achieving this transformation, with artificial intelligence and machine learning serving as our newest and most powerful tools."

As part of the research initiative, MIMO provided each participating company with a comprehensive 30-page playbook analyzing their performance across various categories and metrics—from strategic planning to governance structures and data execution capabilities. These customized reports enable organizations to identify specific opportunities for improvement and prioritize investment areas. Lawler envisions evolving this into a longitudinal study with expanded scope and updated playbooks annually—a substantial yet impactful endeavor powered by LGO's intellectual resources.

"MIT's contribution was invaluable and absolutely critical to this project's success, serving as an extraordinary partner throughout our collaboration," D'Silva acknowledges. "Talented MIT students formed an integral part of our research team, conducting most analyses jointly with McKinsey consultants, which significantly enhanced the overall quality and depth of our work."

This collaborative approach reflects MIMO's fundamental philosophy as an information facilitator and industry partner. The ultimate objective extends beyond technical achievements to encompass "effective industry transformations that deliver not only technological and business objectives but also meaningful social benefits," explains Duane Boning, engineering faculty director at MIT LGO and faculty lead at MIMO.

This integration of research and collaboration represents the natural evolution for LGO, which has consistently positioned itself at the forefront of solving complex global operations challenges. While machine learning currently represents the most significant knowledge gap for many businesses, it's certainly not the first transformative technology the program has addressed. MIMO's expertise lies in helping companies effectively implement these innovations.

"I draw parallels to three decades ago when LGO first emerged, focusing primarily on lean manufacturing principles. Then, about fifteen years ago, supply chain optimization became the dominant paradigm," Boning reflects. "These historical shifts inspired us to consider—not merely for our LGO students but for the broader benefit of industry—how we might better understand, facilitate, and research this current transformation. We recognized the need for a coordinated effort to catalyze change, connecting with complementary research activities. That's where MIMO's true excitement lies: identifying effective ideas, methodologies, and technologies. In many ways, LGO students represent the ideal agents for discovering these innovations."