The integration of artificial intelligence into fabrication tools has transformed laser cutters into sophisticated equipment capable of precisely processing metals, woods, papers, and plastics. Despite their versatility, operators frequently encounter challenges distinguishing between visually similar materials, potentially leading to messy results, unpleasant odors, or even dangerous chemical emissions when incorrect materials are processed.

To address these invisible risks, researchers at MIT's Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed "SensiCut," an innovative AI material detection technology for laser cutting systems. Unlike conventional camera-based methods that often misidentify materials, SensiCut employs advanced machine learning laser cutting systems combined with "speckle sensing" — an optical technique that analyzes a surface's microstructure through a single image-sensing attachment.

The implementation of intelligent material recognition AI like SensiCut offers significant advantages: protecting users from hazardous byproducts, providing material-specific guidance, recommending precise cutting adjustments, and enabling the engraving of multi-material objects such as apparel or smartphone cases.

"By enhancing standard laser cutters with lensless image sensors and artificial intelligence, we can accurately identify visually similar workshop materials while significantly reducing waste," explains Mustafa Doga Dogan, PhD candidate at MIT CSAIL. "Our technology leverages the unique micron-level surface characteristics of each material, which remain distinct even when materials appear identical to the human eye. Without this capability, operators would need to rely on guesswork when selecting from extensive material databases."

Traditional identification methods have included camera systems and physical tags like QR codes applied to material sheets. However, these approaches present limitations: QR codes become unusable once separated from the main sheet during cutting, and incorrectly applied tags inevitably lead to the laser cutter processing materials with inappropriate settings.

To develop their advanced AI fabrication tools, the research team trained SensiCut's deep neural network using an extensive dataset of over 38,000 images across 30 different material types. This training enables the system to differentiate between similar-looking substances such as acrylic, foamboard, and styrene while providing optimized power and speed recommendations for each material.

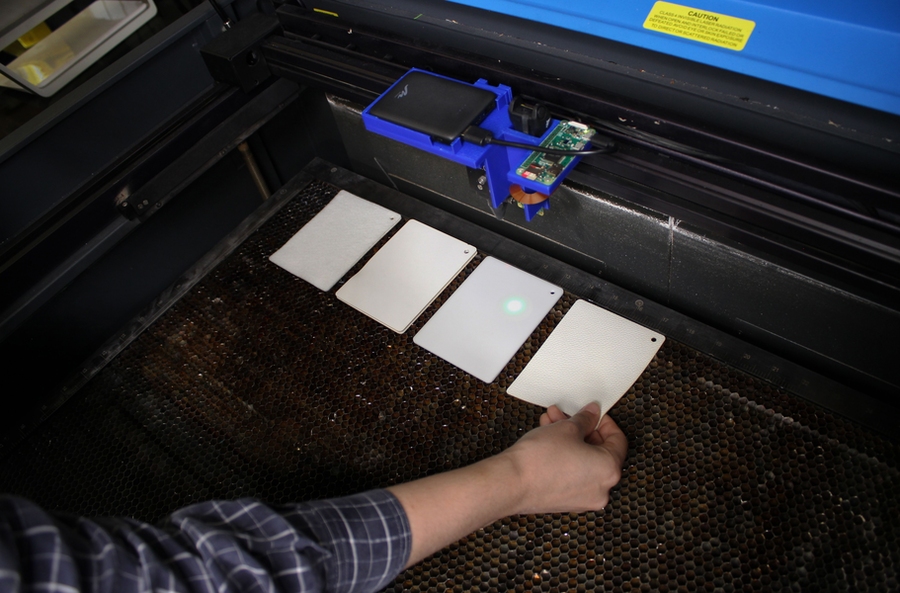

In a practical demonstration, the team constructed a face shield requiring the identification of transparent materials from a workshop inventory. Users selected a design file through the interface, then utilized the "pinpoint" function to direct the laser to analyze a specific point on the material sheet. As the laser interacts with the surface's microscopic features, the reflected light creates a distinctive 2-D image captured by the sensor. This process successfully identified polycarbonate sheets, alerting users to the potentially toxic fumes that would result from laser cutting this material.

The speckle imaging technology was implemented using cost-effective, readily available components including a Raspberry Pi Zero microprocessor board. The team designed and 3D-printed a compact mechanical housing to ensure the system's practical integration with existing laser cutters.

Beyond current applications, the researchers envision expanding this AI material detection technology to other fabrication tools such as 3D printers. Future developments include adding thickness detection capabilities to further enhance the system's material identification accuracy.

Dogan authored the paper with undergraduate researchers Steven Acevedo Colon and Varnika Sinha from MIT's Department of Electrical Engineering and Computer Science, Associate Professor Kaan Akşit of University College London, and MIT Professor Stefanie Mueller.

The research will be presented at the ACM Symposium on User Interface Software and Technology (UIST) in October, with support from the NSF Award 1716413, the MIT Portugal Initiative, and the MIT Mechanical Engineering MathWorks Seed Fund Program.